The ball valve’s 3-pc body allows easy maintenance and replacement of easily wearable components like stems and balls. Such straightforward and low-cost care makes it highly recommended for high-wear applications.

A cryogenic ball valve is engineered to manage extremely low temperatures, typically between -150°C and -196°C, making it ideal for handling cryogenic fluids like liquid nitrogen, oxygen, and LNG. Constructed from durable materials such as stainless steel, these valves feature an extended bonnet to keep the stem seal insulated from the cryogenic fluid, preventing freezing and ensuring reliable operation. They are equipped with low-emission seals to minimize leakage and are designed to withstand the thermal stresses of extreme cold while maintaining smooth operation. Essential in industries such as aerospace and LNG transportation, cryogenic ball valves provide safe and efficient flow control in critical applications.

The Critical Role of Butterfly Valves As essential components in industrial fluid control systems, butterfly valves are widely used in energy, chemical, and water industries due to their compact design and rapid operation. However, extreme operating conditions—such as ultra-low-temperature hydrogen transport and deep-sea high-pressure oil/gas extraction—have exposed limitations in traditional butterfly valves regarding sealing reliability […]

In industrial production, valves serve as critical equipment for controlling fluid flow and must adapt to various operating conditions. High-temperature, high-pressure, and highly corrosive environments impose stringent demands on valve materials. Selecting appropriate materials is essential to ensure stable performance and extend the service life of valves. Valve Materials for High-Temperature Operating Conditions When valves […]

With the continuous improvement in performance requirements for valves in industrial pipeline systems, the double eccentric butterfly valve has emerged as a core control component in petroleum, chemical, power, and other industries due to its exceptional sealing performance, low operating torque, and long service life. However, its design and manufacturing must strictly adhere to international […]

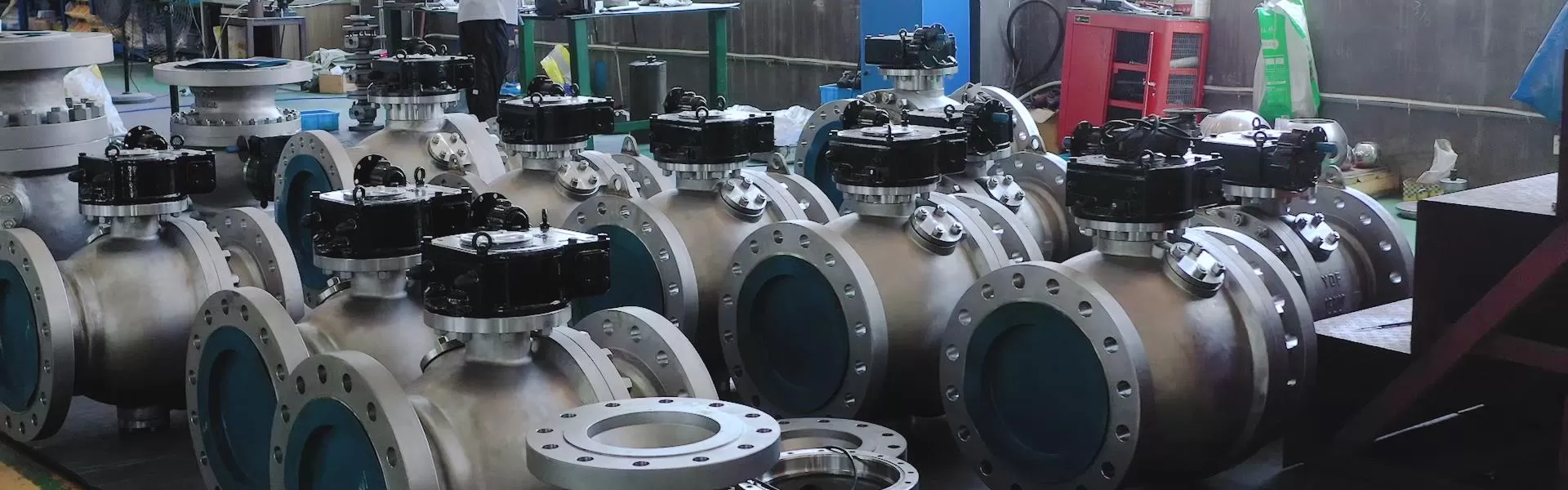

Our products and services comply with international standards and specifications to make sure that we only produce the best and highest quality products and services to our clients.

We offer tailor-made industrial valves to ensure that our product fits your application standards and demand. TIANYU is ISO, API, MSS, and ASME compliant to guarantee you the highest product quality.

As a business partner, TIANYU makes sure that we commit to our clients’ requested deadline because we very much understand the importance of adhering to the timeline required.

TIANYU’s service does not end once our industrial ball valves are being delivered. Also, we offer warranties and provide customer service to our clients as part of our quality service.

Tianyu China Professional Valve Manufacturer and Supplier Conforming ISO APl CE certification standards

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Founded in 2009, Wenzhou Tianyu Valve Technology Co., Ltd. is a professional valve enterprise integrating design, development, production, and sales services, located in the hometown of Chinese valves – Oubei Town, Wenzhou.

Copyright@2024 Tianyu Valve CO.,LTD.All rights reserved.