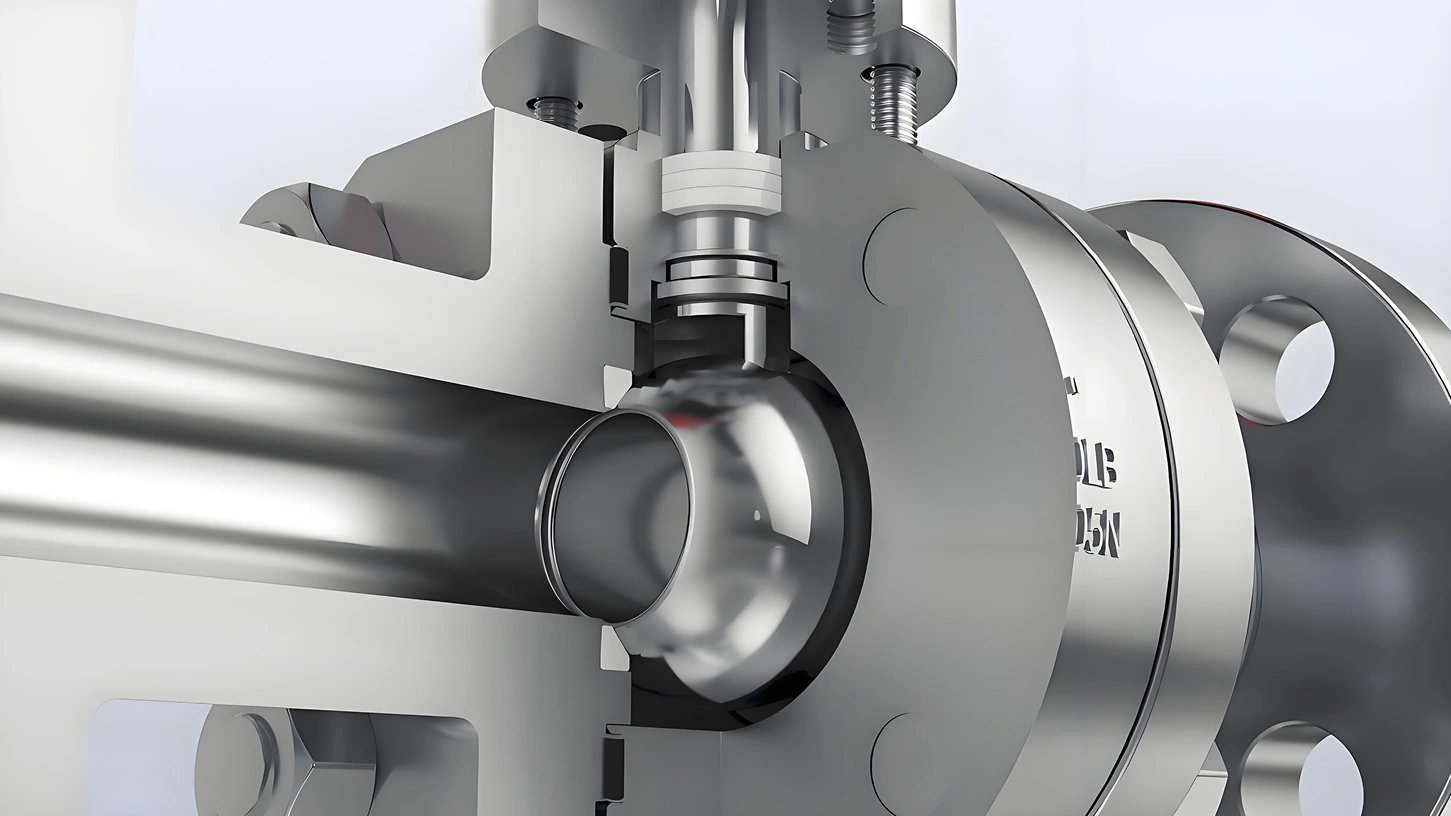

The sealing element is vital for valves, preventing media leakage when closed. Made of durable, corrosion-resistant materials, it withstands pressure, temperature, and corrosion. Its repeated friction during operation makes material choice and manufacturing quality crucial for sealing performance and valve lifespan, regardless of valve type.

A great benefit of a 3-pc ball valve is that you only have to remove the piece at the center when cleaning the line. Three-piece ball valves are typically manufactured using investment cast and designed to withstand pressures up to 1000 psi. It’s suitable for various solid, liquid, and gas applications.