Safety relief valves play a crucial role in maintaining the safety and reliability of various systems. They act as the last line of defense, preventing potential damage by releasing excess pressure when it exceeds safe limits. Understanding where the safety relief valve is usually located is essential, as you will typically find these valves near the pressure vessel or equipment they protect. Their vertical position ensures optimal operation. By knowing where the safety relief valve is usually located, you can prevent accidents and maintain a safer work environment, ensuring system safety and effective maintenance.

Key Takeaways

- Safety relief valves are essential for preventing catastrophic failures by releasing excess pressure in various systems.

- These valves are typically located near pressure vessels, at the end of piping systems, or adjacent to the equipment they protect.

- Regular maintenance and inspection of safety relief valves are crucial for ensuring system safety and preventing equipment damage.

- To locate the safety relief valve, check system diagrams, look for labels, and follow the piping connected to pressure vessels.

- Always consult professionals for repairs or adjustments to safety relief valves to avoid safety hazards and ensure compliance with industry standards.

- Understanding the specific type of system you have (HVAC, plumbing, industrial) can help you identify the correct location of the safety relief valve.

- Maintaining the vertical position of the safety relief valve is vital for its optimal operation and responsiveness to overpressure situations.

Understanding the Safety Relief Valve

What is a Safety Relief Valve?

A safety relief valve is a critical component in many systems, designed to protect against overpressure events. You will find it in various applications, from industrial settings to residential systems. Its primary function is to release excess pressure, ensuring that the system operates within safe limits. This valve acts as a safeguard, preventing potential damage or catastrophic failures. By understanding its role, you can appreciate its importance in maintaining system integrity.

Importance of the Safety Relief Valve in Your System

Safety relief valves are essential for several reasons. First, they prevent catastrophic accidents in high-pressure systems. When pressure builds up beyond safe levels, these valves open to release the excess, averting potential disasters. In industrial settings, they play a crucial role in maintaining optimal system conditions. They ensure that equipment operates efficiently and safely, reducing the risk of downtime and enhancing facility safety.

Moreover, safety relief valves regulate pressure levels in boilers and other critical areas. By doing so, they prevent damage and potential explosions. This regulation is vital for the longevity and reliability of your system. Knowing where the safety relief valve is usually located helps you ensure that it functions correctly. Typically, you will find it near pressure vessels or adjacent to the equipment it protects. Its vertical position is crucial for optimal operation.

Identifying the System Type

Understanding the type of system you have is crucial in locating the safety relief valve. Different systems have unique configurations and requirements, which influence where the safety relief valve is usually located. Here, we explore three common system types: HVAC, plumbing, and industrial systems.

HVAC Systems

In HVAC systems, safety relief valves play a vital role in maintaining pressure levels within safe limits. These systems often include boilers, chillers, and air conditioning units. You will typically find the safety relief valve near the boiler or chiller, ensuring it can effectively release excess pressure. The valve’s vertical position is essential for optimal operation, preventing potential damage to the system. Regular maintenance and inspection of these valves are crucial to ensure the HVAC system operates efficiently and safely.

Plumbing Systems

Plumbing systems rely on safety relief valves to prevent overpressure situations that could lead to leaks or pipe bursts. In residential and commercial plumbing, these valves are often located near water heaters or pressure tanks. You should check system diagrams and look for labels to identify the valve’s location. Ensuring the valve is in a vertical position helps maintain its functionality. Proper installation and regular checks are necessary to avoid potential water damage and ensure the system’s longevity.

Industrial Systems

Industrial systems demand robust safety measures due to their complexity and high-pressure environments. Safety relief valves in these settings are critical for preventing catastrophic failures. You will find them near pressure vessels, at the end of piping systems, or adjacent to the equipment they protect. These valves must be reliable to keep industrial fluid systems operating at peak performance. Regular maintenance and adherence to manufacturer guidelines are essential to prevent unnecessary downtime and ensure facility safety.

By identifying your system type, you can better understand where the safety relief valve is usually located. This knowledge is crucial for maintaining system safety and ensuring effective pressure regulation.

Steps to Locate the Valve

Locating the safety relief valve in your system requires a systematic approach. By following these steps, you can ensure that you find the valve efficiently and accurately.

Check System Diagrams

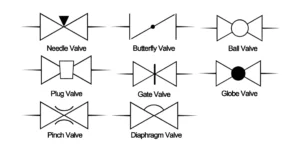

Begin by examining the system diagrams, often referred to as Process and Instrumentation Diagrams (P&IDs). These diagrams provide a visual representation of the system, showing connections between equipment, flow directions, and safety measures. Understanding how to read P&IDs is crucial. They help you trace faults, isolate equipment, and locate items for maintenance. Look for symbols that represent the safety relief valve. These symbols will guide you to where the safety relief valve is usually located within the system.

Look for Labels and Markings

Next, inspect the physical components of your system for labels and markings. Manufacturers often label safety relief valves with specific information, such as pressure ratings and model numbers. These labels can be invaluable in identifying the valve’s location. Pay attention to any markings that indicate the valve’s position relative to other equipment. This step is essential, as it provides direct evidence of where the safety relief valve is usually located.

Follow the Piping

Finally, follow the piping within your system. Safety relief valves are typically installed along the piping that connects to pressure vessels or other critical equipment. Trace the piping from these components to locate the valve. The valve is often positioned at the end of piping systems or adjacent to the equipment it protects. Ensure that the valve is in a vertical position, as this orientation is crucial for its proper operation. By following the piping, you can confirm the valve’s location and ensure it is accessible for maintenance and inspection.

By systematically checking system diagrams, looking for labels, and following the piping, you can effectively locate the safety relief valve in your system. This process not only helps you find the valve but also ensures that you understand its role and importance in maintaining system safety.

Where is the Safety Relief Valve Usually Located?

Understanding where the safety relief valve usually resides in your system is crucial for ensuring safety and efficient operation. These valves have evolved significantly since the Industrial Revolution, when early boilers without them were prone to catastrophic explosions. Today, you can find safety relief valves in strategic locations within various systems.

Near Pressure Vessels

You will often find the safety relief valve near pressure vessels. This placement allows the valve to quickly release excess pressure, preventing potential damage. In the past, early safety valves used weight and spring mechanisms to control pressure. Modern designs have improved significantly, but the principle remains the same: protect the vessel by releasing pressure when necessary. By locating the valve near the pressure vessel, you ensure that it can respond promptly to any overpressure situation.

At the End of Piping Systems

Another common location for safety relief valves is at the end of piping systems. This position allows the valve to manage pressure effectively throughout the entire system. During the evolution of safety valve designs, engineers introduced paired valves with different pressures for better control and safeguarding. Placing the valve at the end of the piping system ensures comprehensive protection, as it can relieve pressure from the entire network. This strategic location helps maintain system integrity and prevents potential failures.

Adjacent to Equipment Being Protected

Safety relief valves are also frequently located adjacent to the equipment they protect. This proximity ensures that the valve can quickly address any pressure issues that arise. Early safety valve mechanisms required continuous attention and maintenance to function correctly. Today, while maintenance is still essential, modern valves are more reliable and efficient. By positioning the valve close to the equipment, you enhance its ability to safeguard against overpressure events, ensuring the equipment operates safely and efficiently.

Knowing where the safety relief valve is usually located in your system is vital for maintaining safety and preventing accidents. Whether near pressure vessels, at the end of piping systems, or adjacent to critical equipment, these valves play a crucial role in protecting your system from overpressure events.

Troubleshooting

When dealing with safety relief valves, troubleshooting can become necessary to ensure they function correctly. Here are some steps you can take to address potential issues:

Consult a Professional

If you encounter problems with your safety relief valve, consulting a professional is crucial. Certified Valve Repair Shops possess the expertise needed to handle adjustments or repairs. They understand the safety risks and code rules associated with these valves. Attempting repairs without proper knowledge can lead to further complications or safety hazards. Therefore, always seek assistance from professionals who specialize in valve maintenance and repair.

“Any adjustments or repairs should be carried out by a certified valve repair shop who understands the safety risks and code rules associated.” — Certified Valve Repair Shop

Check Manufacturer Guidelines

Another essential step in troubleshooting involves checking the manufacturer’s guidelines. These guidelines provide specific instructions on maintaining and troubleshooting your safety relief valve. They include details about pressure settings, installation requirements, and maintenance schedules. By following these guidelines, you can ensure that your valve operates within its designed parameters. This practice helps prevent malfunctions and extends the lifespan of the valve.

For more complex issues, consider reaching out to an ASME Certified Valve Shop. These shops have the authority to test or rebuild safety valves, ensuring they meet industry standards.

“Only an ASME certified valve shop can test or rebuild a safety valve.” — ASME Certified Valve Shop

By consulting professionals and adhering to manufacturer guidelines, you can effectively troubleshoot and maintain your safety relief valve. This approach ensures the valve’s reliability and contributes to the overall safety of your system.

Locating the safety relief valve in your system is crucial for maintaining safety and preventing equipment damage. By understanding its typical locations—near pressure vessels, at the end of piping systems, or adjacent to critical equipment—you ensure effective pressure management. This knowledge helps you prevent overpressure risks and maintain system integrity. Knowing the valve’s location allows for timely maintenance and troubleshooting, ensuring the system operates safely and efficiently. Prioritize regular checks and adhere to manufacturer guidelines to keep your system in optimal condition.

FAQ

What are the three main types of safety relief valves?

You will encounter three primary types of safety relief valves: spring-loaded safety valves, pilot-operated relief valves, and balanced bellows relief valves. Each type serves specific applications and offers unique advantages. Spring-loaded valves are common due to their simplicity and reliability. Pilot-operated valves provide precise control, making them suitable for high-pressure systems. Balanced bellows valves handle backpressure effectively, ensuring consistent performance.

How do safety relief valves differ from pressure relief valves?

Safety relief valves and pressure relief valves serve different purposes. Safety relief valves act as emergency devices. They release pressure immediately during system failures to prevent catastrophic disasters. Pressure relief valves, on the other hand, regulate pressure within a system under normal operating conditions. Understanding this distinction helps you choose the right valve for your application.

Why is the vertical position important for safety relief valves?

The vertical position is crucial for safety relief valves because it ensures optimal operation. When installed vertically, the valve can function correctly, allowing gravity to assist in the valve’s opening and closing. This orientation prevents potential malfunctions and ensures that the valve responds promptly to overpressure situations.

Where should I look for the safety relief valve in my system?

You should start by examining system diagrams and looking for labels and markings. These resources often indicate the valve’s location. Typically, you will find the safety relief valve near pressure vessels, at the end of piping systems, or adjacent to the equipment it protects. Following the piping can also lead you to the valve’s location.

Can I adjust or repair a safety relief valve myself?

You should not attempt to adjust or repair a safety relief valve yourself. These tasks require specialized knowledge and expertise. Always consult a professional or a certified valve repair shop. They understand the safety risks and code rules associated with these valves. Attempting repairs without proper knowledge can lead to further complications or safety hazards.

How often should I inspect my safety relief valve?

Regular inspection of your safety relief valve is essential. You should follow the manufacturer’s guidelines for maintenance schedules. Typically, annual inspections are recommended. However, high-pressure systems may require more frequent checks. Regular inspections ensure that the valve operates within its designed parameters and prevents potential malfunctions.

What should I do if my safety relief valve is leaking?

If you notice a leak in your safety relief valve, consult a professional immediately. Leaks can indicate a malfunction or improper installation. A certified valve repair shop can assess the situation and perform necessary repairs. Ignoring leaks can lead to system inefficiencies or safety hazards.

Are there any specific guidelines for installing a safety relief valve?

Yes, you should follow the manufacturer’s installation guidelines closely. These guidelines provide specific instructions on positioning, pressure settings, and connection requirements. Proper installation ensures that the valve functions correctly and maintains system safety. Deviating from these guidelines can compromise the valve’s performance and lead to potential risks.

Can safety relief valves be used in all types of systems?

Safety relief valves are versatile and can be used in various systems, including HVAC, plumbing, and industrial applications. However, you must select the appropriate valve type for your specific system requirements. Consider factors such as pressure levels, system configuration, and environmental conditions when choosing a valve.

What role do safety relief valves play in system maintenance?

Safety relief valves play a critical role in system maintenance by preventing overpressure events. They ensure that the system operates within safe limits, reducing the risk of equipment damage and downtime. Regular maintenance and inspection of these valves are crucial for maintaining system integrity and safety.