Valve Safety: A Solid Defense Line for Industrial Production

In the vast system of modern industrial production, valves serve as the core components for regulating and controlling fluid flow, and their safety is undoubtedly crucial to ensuring the smooth operation of the entire production process and the safety of personnel. With the rapid development of industrial technology and the continuous improvement of safety standards, valve safety has received increasing attention from all sectors of society. This article aims to delve into the core significance of valve safety, common types of safety valves, and how to ensure the continuous and safe operation of valves through systematic and refined management strategies.

Valve Safety: A Solid Defense Line for Industrial Production

I. The Strategic Significance of Valve Safety

As the “goalkeeper” in industrial production, the safety performance of valves is directly related to the stability and reliability of the entire production system. Once a valve fails or malfunctions, it may lead to serious consequences such as fluid leakage, pressure loss control, equipment damage, and even fire and explosion, causing incalculable losses to enterprises and employees. Therefore, ensuring the safety performance of valves is not only a necessary prerequisite for preventing accidents and ensuring production safety, but also an important guarantee for enterprises to achieve long-term stable development and fulfill their social responsibilities.

II. Diverse Choices of Safety Valves

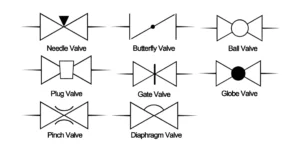

To meet the safety needs of different industrial scenarios, various types of safety valves have emerged in the market. Among them, safety valves, with their unique automatic opening and discharge function, can quickly respond when the system pressure exceeds the safety threshold, effectively protecting pressure vessels and pipeline systems from damage. Relief valves control or limit the pressure inside the equipment to ensure that the system always operates in a safe state. Stop valves can quickly cut off the flow of media in emergency situations to prevent the situation from further deteriorating. Adjustable valves such as butterfly valves and ball valves can achieve precise flow regulation while ensuring safety.

III. Comprehensive Protection of Valve Safety

To ensure that the safety performance of valves is fully utilized, enterprises need to adopt a series of systematic and refined management strategies. First, during the selection and design stage, appropriate valve types and materials should be selected based on actual working conditions to ensure stable operation under specific temperature, pressure, and media conditions. Secondly, regular inspections, maintenance, and replacement of worn parts for valves can help detect and resolve potential safety hazards in time. At the same time, correctly installing valves and ensuring secure connections between valves and pipeline systems are also crucial to ensuring valve safety. In addition, systematic valve usage and safety training for operators is essential to improve their operational skills and emergency response capabilities.

IV. Conclusion

Valve safety is a solid defense line for industrial production and a key factor for enterprises to achieve sustainable development. By selecting appropriate safety valves, strengthening routine maintenance and inspections, and improving operators’ safety awareness and emergency response capabilities, the risk of industrial accidents can be significantly reduced, ensuring production safety. In the increasingly severe safety situation, enterprises should pay more attention to investment and management in valve safety to ensure the stable operation of the entire production system and the safety of personnel.