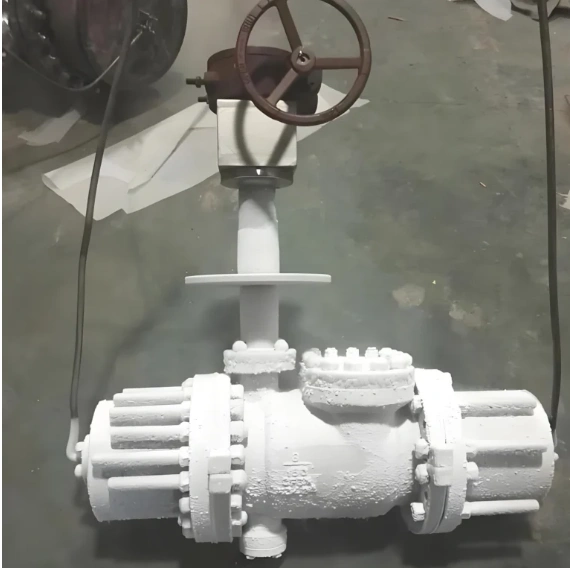

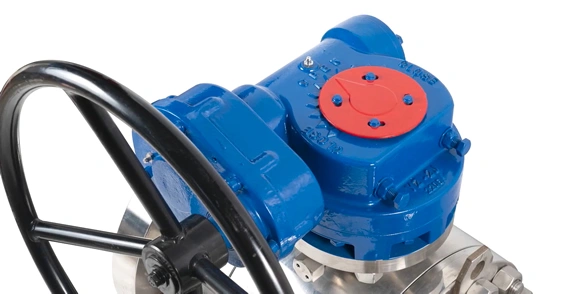

TIANYU cryogenic ball valves are specially designed for LNG applications, with an operating temperature of -196°C and a pressure rating of Class 1500. They adopt special low-temperature resistant materials to ensure stable performance and reliable sealing at low temperatures. Advanced manufacturing processes guarantee high precision and quality. Their advantages lie in excellent low-temperature adaptability, precise flow control, high reliability, long service life, convenient maintenance, and high cost-effectiveness. They are widely used in all links of LNG production, storage, transportation, and application, making them an ideal choice for ensuring the safe and efficient operation of LNG systems. They can be customized according to different working conditions to meet the requirements of various projects.