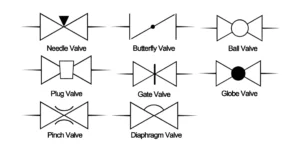

Introduction to Butterfly Valves and Their Working Principle, Highlighting Their Advantages

Introduction:

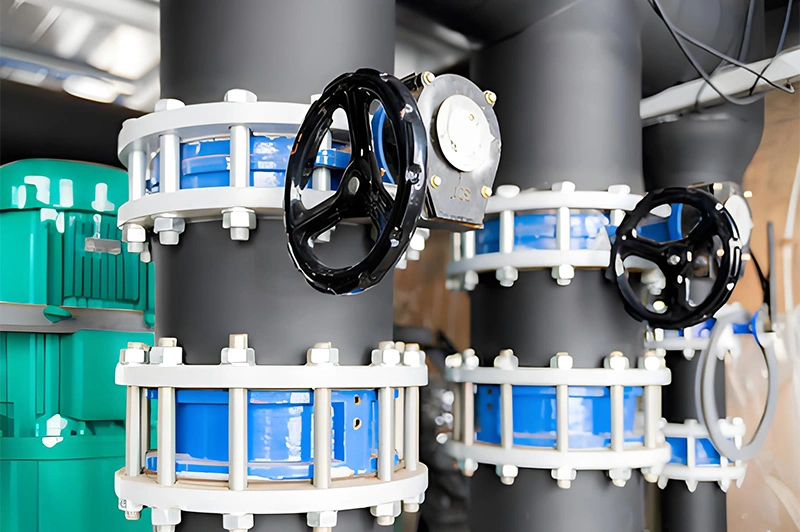

Butterfly valves, also known as flap valves or butterfly-shaped gates, are versatile flow control devices used extensively in various industrial applications. They offer a streamlined and efficient means of regulating the flow of fluids or gases within pipelines. The simplicity of their design, coupled with their ease of operation, has made butterfly valves a popular choice across industries such as petrochemicals, power generation, metallurgy, food processing, and water supply systems.

Working Principle:

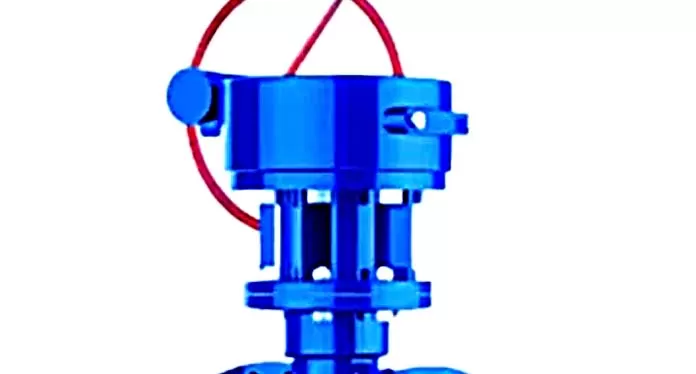

The working principle of a butterfly valve revolves around its central disc-shaped element, known as the disc or butterfly. This disc is mounted on a pivot or valve stem, which allows it to rotate within the valve body. When the handle or actuator is operated, it rotates the disc around its axis. As the disc rotates, it either aligns with the flow path (fully open position), blocks the flow path (fully closed position), or partially obstructs it to regulate the flow rate. The degree of opening or closing determines the amount of fluid or gas that can pass through the valve.

Advantages of Butterfly Valves:

- Compact and Lightweight Design: Butterfly valves boast a compact design with minimal parts, making them lightweight and space-saving. This feature is particularly advantageous in applications where space is limited or weight reduction is crucial.

- Easy Operation and Maintenance: The simplicity of the design translates into ease of operation and maintenance. The disc can be quickly rotated to adjust the flow, and the valve’s straightforward construction facilitates quick repairs and replacements when necessary.

- Efficient Flow Control: In the fully open position, the thin disc profile creates minimal resistance to fluid flow, resulting in low-pressure drop and energy loss. Additionally, the disc’s position can be adjusted to provide precise flow control, making butterfly valves suitable for applications requiring fine-tuning of flow rates.

- Good Sealing Performance: Depending on the application, butterfly valves can be equipped with various sealing materials, including soft elastomers and metal-to-metal seals. These options ensure effective sealing in a wide range of temperature, pressure, and media conditions.

- Wide Range of Materials and Configurations: Butterfly valves are available in a variety of materials, including cast iron, stainless steel, and specialty alloys, to suit diverse application requirements. Furthermore, they come in different configurations, such as wafer, lug, and double flange, offering flexibility in system integration.

- Cost-Effective: Due to their straightforward design and manufacturing process, butterfly valves are typically more cost-effective than other types of valves. This, combined with their long service life and low maintenance requirements, makes them an economically viable choice.

- Versatile Applications: Butterfly valves can handle a wide range of fluids and gases, from clean liquids to slurries and even corrosive or abrasive media. Their ability to withstand extreme temperatures and pressures makes them suitable for use in harsh environments.

Chart Layout:

- Axes:

- X-axis: Represents the temperature range, typically spanning from low temperatures (e.g., -196°C for cryogenic applications) to high temperatures (e.g., 500°C for high-temperature steam).

- Y-axis: Represents the pressure rating, typically categorized by industry standards (e.g., PN10, PN16, PN25, Class 150, Class 300, etc.).

- Color Coding:

- Each color or shade on the chart corresponds to a specific media type (e.g., blue for water, green for oil, red for corrosive gases, yellow for chemicals with specific properties).

- Symbols or Bubbles:

- Sizes of symbols or bubbles within the chart can represent the range of valve sizes available (e.g., larger symbols for larger valves, such as DN1000, and smaller symbols for smaller valves, such as DN15).

- Key or Legend:

- A clear key or legend at the bottom or side of the chart explains the meaning of each color, symbol, and size, making it easy for viewers to interpret the information.

- A clear key or legend at the bottom or side of the chart explains the meaning of each color, symbol, and size, making it easy for viewers to interpret the information.

Versatile Applications and Reasons for Adoption:

-

- Water and Wastewater Treatment: Butterfly valves are widely used in water and wastewater treatment facilities due to their ability to handle large volumes of fluid efficiently. Their compact design and ease of operation make them suitable for tight spaces and quick flow adjustments.

- Petrochemical and Chemical Industries: In these industries, butterfly valves are chosen for their resistance to corrosive media and high-temperature applications. Their ability to handle a wide range of chemicals and gases, combined with reliable sealing, makes them essential for safe and efficient process control.

- Food and Beverage Processing: Butterfly valves are preferred in food and beverage processing plants due to their ease of cleaning and compliance with hygienic standards. Smooth surfaces and minimal crevices facilitate thorough cleaning and disinfection, ensuring product quality and safety.

- Power Generation: In power plants, butterfly valves are used to control the flow of cooling water, steam, and other fluids in piping systems. Their precise flow control capabilities and ability to withstand high pressures make them ideal for critical processes in power generation.

- Mining and Minerals Processing: In mining and minerals processing operations, butterfly valves are used to regulate the flow of slurries and abrasive materials. Their rugged construction and resistance to wear make them suitable for demanding applications in these industries.

In conclusion, butterfly valves are a versatile and efficient flow control solution with numerous advantages. Their compact design, ease of operation and maintenance, efficient flow control capabilities, and cost-effectiveness have made them a popular choice across various industrial sectors. The reasons for their adoption in these sectors stem from their ability to meet specific application requirements, ensuring safe, reliable, and efficient process control.

- Axes:

Chart Layout:

Chart Layout: