Definition of Gate Valve

A gate valve is a type of valve that controls the on-off of the medium in the pipeline through the vertical lifting and lowering movement of the gate. Its opening and closing member (the gate) moves in the vertical direction along the center line of the passage to achieve the functions of full opening or full closing. Gate valves cannot be used for regulation and throttling, but only for full opening and full closing cut-off.

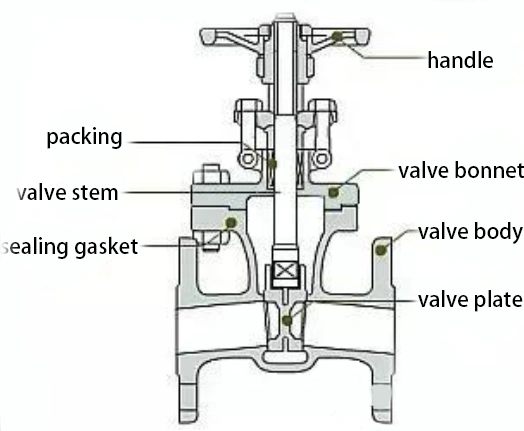

Basic Structure of Gate Valve

· Valve body: The valve body is the shell of the gate valve, providing support and pressure-bearing structure for the entire valve. It is usually made of cast iron, cast steel, stainless steel or other alloy materials based on application requirements and fluid characteristics.

· Gate: The gate is the key component of the gate valve, controlling the fluid flow through its lifting and lowering. The gate is usually made of the same material as the valve body or a suitable material selected according to the medium characteristics.

· Valve stem: The valve stem connects the gate and the handwheel or driving device, transmits the operating force, and enables the gate to lift and lower. The material of the valve stem needs to have sufficient strength and corrosion resistance.

· Sealing surface: The sealing surface is located on the gate and the valve body. When the gate valve is closed, a seal is formed between the sealing surfaces to prevent the fluid from passing through. The material selection of the sealing surface is crucial to the sealing performance of the valve.

· Valve seat: The valve seat is the component inside the valve body used to support the gate and form a seal with it. It cooperates with the gate to form a sealing surface to ensure the sealing performance when the valve is closed.

· Packing box: The packing is the material filled in the packing box, usually made of PTFE, asbestos, carbon fiber, etc., used to seal the gap between the valve stem and the valve cover to prevent medium leakage.

Working Principle of Gate Valve

The industrial gate valve mainly controls the on-off of the fluid through the vertical movement of the gate. Its basic structure includes components such as the valve body, gate, valve stem, sealing device and driving device. When the gate valve is in the closed state, the gate descends in the guide rail inside the valve body until the sealing surface of the gate is tightly fitted with the sealing surface of the valve body to prevent the fluid from passing through. When it is necessary to open the gate valve, the valve stem moves upward through the driving device, driving the gate to rise, and the fluid can flow in the internal passage of the valve body. This design makes the gate valve most reliable when it is fully open or fully closed. However, in the partially open state, the gate will be subject to greater erosion from the fluid, affecting its sealing performance and service life. Therefore, the gate valve is mainly used to achieve complete blocking or complete opening of the fluid, rather than for flow regulation.

Advantages and Disadvantages of Gate Valve

Advantages of gate valve:

·Low fluid resistance: The internal passage of the gate valve is almost straight. When fully open, the fluid can pass through without obstruction, and the fluid resistance is very small.

·Bidirectional sealing: The gate valve can effectively seal in both directions of the medium flow, not limited by the flow direction, and is suitable for pipelines with bidirectional flow.

Smooth switching action: The switching action of the gate valve is smooth without violent impact, and is suitable for frequent operation occasions.

·Suitable for high pressure and high temperature environments: Due to the strong structure of the gate valve, it can maintain good sealing performance in high-pressure and high-temperature working environments.

·Good sealing performance: The sealing surface of the gate valve usually adopts hard alloy materials, which have good wear resistance and a long service life.

Disadvantages of gate valve:

Long opening and closing time: Due to the large opening and closing stroke of the gate valve, it usually takes a long time to fully open or close.

Complex structure: The internal structure of the gate valve is relatively complex, and its manufacture and maintenance are relatively troublesome.

Large volume: Due to the structural characteristics of the gate valve, its volume and weight are usually large, especially in large-diameter pipelines.

Not suitable for regulating flow: The gate valve is mainly used for fully open or fully closed occasions, and is not suitable for precise flow regulation. Because in the partially open state, the gate and the fluid may generate strong vibration.

The sealing surface is prone to damage: Although the sealing surface material is hard, the sealing surface is prone to wear under frequent opening and closing or when the fluid contains hard particles, thereby affecting the sealing performance.

Types of Industrial Gate Valves

Wedge gate valves, forged steel gate valves, knife gate valves, pressure-sealed gate valves and slab gate valves are common types of industrial valves. They are widely used in various industrial fluid control systems due to their different structural characteristics and operation methods.

· Wedge gate valve: The sealing surface is wedge-shaped and forms a specific angle with the vertical center line. This structure gives it excellent sealing performance and makes it favored in working conditions where strict control of medium leakage is required. It is often used in fields such as petrochemical and natural gas transmission.

· Forged steel gate valve: Made of high-quality forged steel, it has high strength and excellent pressure resistance ability, and can operate stably in extreme environments of high temperature and high pressure. It is an important part of the key pipeline systems in industries such as power and metallurgy.

· Knife gate valve: With its unique knife-shaped inclined notch design at the bottom of the gate, it can effectively cut off the fluid containing solid particles or fibrous substances and plays an indispensable role in industries such as sewage treatment, mining and pulp manufacturing.

· Pressure-sealed gate valve: Skillfully uses the medium pressure to enhance the sealing effect to ensure reliable fluid control under high-pressure, high-temperature and extremely strict sealing requirements, such as in the pipeline system of nuclear power plants.

·Slab Gate Valve: With its characteristics of low flow resistance and rapid operation, it shows significant advantages in industrial fluid control systems that have high requirements for flow control and need frequent operation, such as in the fields of oil and gas transmission and fine chemical industry.

Common Problems and Solutions of Industrial Gate Valves

Problems related to gate valve leakage

· Leakage at the sealing surface or connection

Reason: The sealing surface or gasket is damaged, and the connection parts are not fastened according to the specifications.

Solution: Inspect and replace the damaged sealing surface or gasket, and ensure that all connection parts are fastened in accordance with the manufacturer’s specifications.

· Packing leakage

Reason: The packing cannot effectively seal due to wear or aging.

Solution: Replace the new packing and reinstall it in accordance with the technical specifications to ensure the tightness of the packing.

Problems related to gate valve operation

· Stem jamming

Reason: Rust and corrosion on the valve stem.

Solution: Clean the rust and corrosion on the valve stem and add an appropriate amount of lubricant to ensure smooth operation of the valve stem.

· Insensitive valve operation

Reason: There are obstacles inside the valve stem and the valve.

Solution: Check whether there are obstacles inside the valve stem and the valve, add lubricant, and improve the installation method of the valve.

Component connection related problems

· Gate plate detachment

Reason: The connection at the gate plate and the valve body is loose.

Solution: Recheck and fasten the connection bolts to ensure the correct fit between the gate plate and the valve seat.

Fluid passage related problems

· Fluid passage blockage

Reason: The internal passage of the valve is blocked by solid particles or sediments.

Solution: Regularly clean the inside of the valve and filter the fluid to prevent impurities from entering the valve.

Problems related to gate valve corrosion

· Valve corrosion

Reason: The valve material is corroded due to the environment or the chemical properties of the medium.

Solution: Use corrosion-resistant materials or coatings, regularly inspect the valve condition, and repair or replace the damaged parts in time.

Sealing surface performance related

· Scratches on the sealing surface

Reason: The sealing surface is scratched due to wear or foreign hard objects.

Solution: Polish and repair the scratches, and replace the new sealing surface if necessary.

Maintenance and Maintenance of Industrial Gate Valves

Daily inspection and maintenance:

1. Appearance inspection: Regularly inspect whether the outside of the valve has corrosion, cracks or other damages.

2. Operation inspection: Ensure that the valve operates smoothly without jamming.

3. Leakage inspection: Check for any signs of leakage when the valve is closed.

Regular maintenance:

1. Cleaning: Regularly clean the valve to remove dust, rust and sediments.

2. Lubrication: Add lubricating oil or grease to the valve stem and other moving parts regularly.

3. Fastening: Check all connection bolts and nuts to ensure they are fastened in place to prevent loosening.

Seasonal or periodic inspection:

1. Sealing test: Regularly conduct sealing tests on the valve to ensure its performance.

2. Component replacement: Replace worn seals and other wearing parts according to usage and manufacturer’s recommendations.

3. Performance evaluation: Evaluate the performance of the valve and check for signs of increased operating torque or decreased sealing performance.

Long-term maintenance strategy:

1. Record maintenance history: Record all maintenance and maintenance activities, including the date and type of component replacement.

2. Training operators: Ensure that all operators understand the correct operation method and maintenance requirements of the valve.

3. Follow the manufacturer’s guide: Follow the maintenance and maintenance guide provided by the valve manufacturer.

Special precautions:

1. Avoid excessive operation: Avoid excessive operation of the valve, which may cause component damage.

2. Use appropriate tools: Use appropriate tools for maintenance to avoid damaging valve components.

3. Environmental adaptability: Adjust the maintenance plan according to the valve’s operating environment (such as temperature, humidity, etc.).

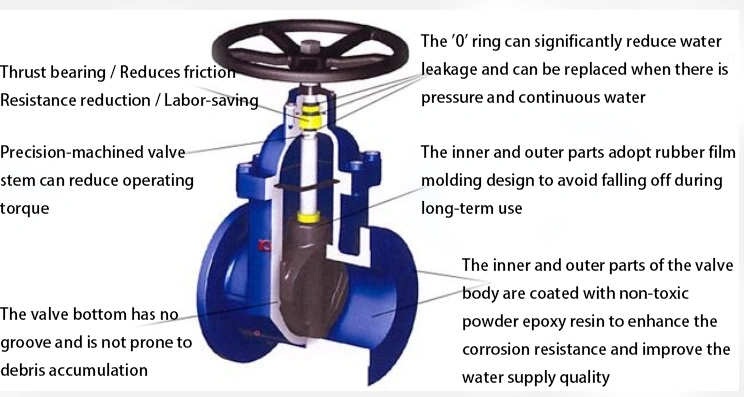

Characteristics and Advantages of Tianyu Gate Valves

Tianyu gate valves have won a good reputation in the market with its high-quality materials, advanced design, strict quality control and good after-sales service.

Specific advantages:

1. Material advantage: Made of high-quality materials to ensure the pressure resistance, corrosion resistance and sealing performance of the valve.

2. Design advantage: The design of the gate and sealing structure is reasonable, the operation is light and flexible, and the rapid and accurate fluid control is realized.

3. Quality control: From raw material procurement to product delivery, each link has undergone strict testing to ensure product quality.

4. After-sales service: Provide perfect after-sales service to ensure that users receive timely technical support during use.

We have provided a comprehensive explanation of the definition, basic structure, working principle, types of Tianyu gate valves, common problem solutions, maintenance methods, and characteristic advantages of gate valves to help you understand and choose Tianyu gate valves. Choosing Tianyu gate valves means choosing a fluid control solution that has been verified by the market and supported by high quality and advanced technology. It has excellent performance, can meet and exceed customer expectations, contribute to industrial development, help you make wise decisions in industrial production, and achieve efficient and stable fluid control.