Key Takeaways

- The valve market is growing fast and may hit $110.5 billion by 2031, thanks to spending on energy and infrastructure.

- Picking trusted valve makers gives you good products for safety and efficiency.

- New tech, like smart valves that monitor in real-time, helps work better and cuts delays.

- Certifications like ISO 9001 and API prove valve makers follow global quality and safety rules.

- Choosing the best valve maker saves money on repairs and boosts work output over time.

Tianyu Valve

Tianyu Valve stands out for its expertise in forged valves, particularly designed for the oil, natural gas, and nuclear industries. These valves are meticulously engineered to withstand extreme conditions, making them the ideal choice for oil and gas extraction, crude oil transportation, and nuclear power generation. Tianyu Valve focuses on precision and durability, ensuring reliable solutions tailored to meet the operational needs of its clients.

Main Products and Certifications

Tianyu Valve offers a range of forged valves, including gate valves, globe valves, and check valves. These products are designed to deliver exceptional performance in high-pressure and high-temperature environments. For example, Tianyu’s gate valves are known for their excellent sealing capabilities, while their globe valves provide precise flow control. Tianyu’s check valves prevent backflow, ensuring system safety and operational efficiency.

Specialization and Long-term Reliability

Tianyu Valve’s valves are particularly suited for applications that require long service life and minimal maintenance, making them a cost-effective choice for operations in the oil, natural gas, and nuclear industries.

Certifications and Compliance

Tianyu Valve holds several international certifications, including ASME, ISO 9001, PED, API, and SIL, demonstrating the company’s commitment to quality, safety, and compliance. These certifications ensure that Tianyu’s products meet global standards, giving clients confidence in their reliability and compliance.

In the nuclear sector, Tianyu Valve has made significant contributions by providing specialized valves for reactor technologies such as PWR, EPR, and CANDU. In the oil and gas sector, their solutions prioritize efficiency and safety while adhering to international standards, cementing Tianyu’s leadership in the valve manufacturing industry.

Flowserve Corporation

Founded in 1790, Flowserve Corporation is one of the oldest and most respected names in the valve industry. Headquartered in Irving, Texas, USA, the company generates annual sales of $4 billion. It serves over 10,000 customers across more than 50 nations, making it a global leader in the field. Flowserve’s reputation as one of the top 10 pressure control valve manufacturers stems from its commitment to quality and innovation.

Key Products and Certifications

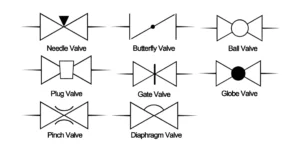

Flowserve offers a wide range of products, including ball valves, butterfly valves, globe valves, and plug valves. These products cater to industries such as oil and gas, water treatment, and manufacturing. As one of the best industrial ball valve manufacturers, Flowserve ensures its products meet stringent industry standards. The company holds certifications like API, ISO 9001, ASME, and PED, which highlight its dedication to certifications and standards compliance. These credentials assure you of the reliability and safety of their pressure control valves.

Innovations and Contributions

Flowserve stands out among the top globe valve manufacturers due to its focus on innovation. The company has introduced advanced materials and real-time monitoring systems in its valve technology. These features enable predictive maintenance, reducing downtime and improving operational efficiency. Additionally, Flowserve’s energy-efficient designs contribute to sustainability efforts, aligning with the growing demand for eco-friendly solutions. The company also specializes in pumps, seals, and hydraulic decoking systems, further solidifying its position as a leading industrial ball valve manufacturer.

Emerson Electric Co.

Overview

Established in 1890, headquartered in St. Louis, Missouri, USA.

Emerson Electric Co. has built a reputation as a global leader in industrial automation and valve manufacturing. With over 130 years of experience, the company is renowned for its FISHER brand, which offers reliable and innovative valve solutions. Its extensive global service network ensures you receive consistent support, no matter where your operations are located.

Key Products and Certifications

Solenoid valves and advanced control valves.

Emerson specializes in high-quality control valves designed to meet the demands of modern industries. Its product portfolio includes solenoid valves and advanced control valves, which are widely used in sectors like oil and gas, water treatment, and power generation. These valves are engineered for precision and durability, ensuring optimal performance in critical applications.

Certifications include API, ISO 9001, ASME, PED, CE, and Lloyds’ Register.

The company adheres to stringent international standards, holding certifications such as API, ISO 9001, ASME, PED, CE, and Lloyds’ Register. These certifications reflect Emerson’s commitment to quality and safety, giving you confidence in their products’ reliability.

Innovations and Contributions

Focus on automation integration and energy-efficient technologies.

Emerson leads the way in automation integration, helping industries transition to smarter and more efficient systems. Its focus on energy-efficient technologies reduces operational costs while supporting sustainability goals.

AVK Group

Overview

Founded in 1941, headquartered in Denmark.

AVK Group has established itself as a global leader in valve manufacturing, specializing in solutions for water, gas, and sewage industries. With decades of expertise, the company has built a strong reputation for delivering reliable and innovative products. Its strategic acquisition of Talis Group further strengthened its market position, particularly in Southern Europe, and expanded its presence in the desalination sector.

Specializes in water, gas, and sewage industries.

AVK Group serves a diverse range of industries, ensuring its products meet the unique demands of each sector. You can rely on their expertise to provide solutions tailored to your specific needs.

- Key industries served:

- Water and gas supply for municipal and industrial applications.

- Industrial water treatment for sectors like power generation, oil and gas, and mining.

- Advanced manufacturing, including components for food processing, transport, and wind energy.

| Industry Served | Description |

|---|---|

| Water and Gas Supply | Products for water and gas supply, sewage, and fire protection markets. |

| Industrial Water Treatment | Solutions for power generation, oil & gas, marine, pulp and paper, mining, chemical industry. |

| Advanced Manufacturing | Components for food, transport, and wind energy industries. |

Key Products and Certifications

Valves, hydrants, and accessories.

AVK Group offers a comprehensive product portfolio that includes valves, hydrants, and accessories. These products are designed to ensure durability and efficiency in critical applications. Whether you need solutions for water distribution or fire protection, AVK’s products deliver exceptional performance.

Certifications include ISO 9001, UKCA, and UL.

AVK Group stands out for its commitment to quality and compliance with international standards. The company holds certifications such as ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety. These certifications demonstrate AVK’s dedication to delivering products that meet the highest industry standards.

| Certification/Standard | Description |

|---|---|

| ISO 9001 | Quality management |

| ISO 29001 | Quality management in the oil & gas industry |

| ISO 14001 | Environmental management |

| ISO 50001 | Energy management |

| ISO 45001 | Occupational health and safety management |

Tip: AVK Group’s extensive certifications ensure you receive products that prioritize safety, sustainability, and efficiency. This makes them a trusted partner for industries worldwide.

KITZ Corporation

Overview

Established in 1951, headquartered in Japan.

KITZ Corporation has been a cornerstone of the valve manufacturing industry since its inception in 1951. Headquartered in Japan, it has grown into the largest valve manufacturer in the country. This achievement stems from its extensive manufacturing capabilities, dedication to quality, and a robust global network. KITZ produces a wide range of valves, including carbon steel and stainless steel options, to meet diverse industrial needs.

You benefit from their advanced production systems, which include in-house foundries and a just-in-time production approach. These systems enhance efficiency and ensure timely delivery of high-quality products. KITZ’s commitment to innovation and reliability has solidified its position as a leader in the global valve market.

Key Products and Certifications

Brass forging and globe valves.

KITZ Corporation’s brass forging and globe valves are renowned for their superior quality and performance. These valves are manufactured in modern facilities equipped with automated production technologies, ensuring uniformity and precision. The use of advanced materials, such as Aramid Fiber PTFE for gland packing, provides leak-free sealing and reduces operating torque. This makes the valves highly reliable for various applications.

| Feature | Description |

|---|---|

| Manufacturing Process | Modern factories with automated production facilities ensure superior quality and uniformity. |

| Materials Used | Aramid Fiber PTFE is used for asbestos-free gland packing, providing leak-free sealing and reduced operating torque. |

| Pressure Rating | Rated for W.O.G. (non-shock cold water, oil, and gas) and saturated steam pressure service, with a maximum of 300psi at temperatures up to 300°C. |

| Inspection and Testing | Strict quality control throughout production, including chemical composition and mechanical properties inspection, ensuring long service life and quality performance. |

| Human Engineering in Design | Computer-designed hand wheels combine operational efficiency with high mechanical strength for reliability. |

Certifications include ISO 9001 and API 6D.

KITZ Corporation holds certifications like ISO 9001 and API 6D, which reflect its commitment to maintaining high standards in quality management and product performance. These certifications ensure you receive valves that meet stringent international requirements, providing peace of mind for critical industrial applications.

Tip: KITZ’s focus on quality and innovation ensures you get durable and efficient valve solutions tailored to your operational needs. Their products are designed to perform reliably under demanding conditions, making them a trusted choice for industries worldwide.

Bray International

Overview

Established in 1986, headquartered in Houston, Texas, USA.

Bray International has been a trusted name in the valve manufacturing industry since its inception in 1986. Headquartered in Houston, Texas, the company focuses on delivering advanced automation solutions for the energy and chemical industries. Its expertise in flow control and valve technology ensures you receive reliable and efficient products tailored to your operational needs.

Focuses on automation solutions for energy and chemical industries.

Bray International specializes in providing cutting-edge automation solutions that enhance operational efficiency. These solutions cater to industries like oil and gas, power generation, and chemical processing. You can rely on Bray’s commitment to innovation and quality to meet the demands of these critical sectors.

| Product Type | Description |

|---|---|

| High-Performance Actuators | Designed for mission-critical power plant operations, ensuring reliability and efficiency. |

| Flow Control Solutions | Includes dependable valves, actuators, and accessories tailored for energy sector applications. |

| Reliable Flow Control Solutions | Offers quality valves, actuators, and accessories for oil, gas, and downstream industries. |

| Industry Commitment | Bray is dedicated to providing effective flow control solutions globally. |

Key Products and Certifications

Butterfly valves, ball valves, and knife gate valves.

Bray International offers a diverse range of products, including butterfly valves, ball valves, and knife gate valves. These products are engineered to deliver exceptional performance in demanding environments. As a leading industrial ball valve manufacturer, Bray ensures its valves meet the highest standards of durability and efficiency. Whether you need precise flow control or robust sealing capabilities, Bray’s products provide reliable solutions for your operations.

Certifications include ASME, ISO 9001, API, and CE PED.

Bray International implements a comprehensive Quality Management Program to ensure every product meets or exceeds industry standards. The company complies with ISO 9001:2015, which emphasizes continuous improvement in product quality and customer satisfaction. Additionally, Bray holds certifications such as API 6D for pipeline valves, ISO 10497 for valve testing, and ATEX 94/9/EC for equipment used in explosive atmospheres. These certifications highlight Bray’s dedication to safety, reliability, and compliance.

| Certification | Description |

|---|---|

| API 6D | Pipeline Valves |

| ISO 10497 | Testing of Valves |

| ATEX 94/9/EC | Equipment for Explosive Atmospheres |

Bray International’s focus on automation, quality, and innovation solidifies its position as one of the best industrial ball valve manufacturers. Its products and solutions ensure you achieve operational excellence while maintaining safety and efficiency.

IMI plc

Overview

Founded in 1862, headquartered in Rancho Santa Margarita, California, USA.

IMI plc has a long-standing history of delivering innovative valve solutions. With its headquarters in Rancho Santa Margarita, California, the company has become a global leader in manufacturing valves designed for extreme conditions. You can rely on IMI plc for products that perform exceptionally well in challenging environments, such as high-pressure or high-temperature applications. Its expertise ensures that your operations remain safe and efficient.

Specializes in valves for extreme conditions.

IMI plc focuses on creating valves that withstand the harshest industrial conditions. Whether you operate in the energy, chemical, or manufacturing sectors, their products are tailored to meet your specific needs. This specialization makes IMI plc a trusted partner for industries requiring durable and reliable solutions.

Key Products and Certifications

Integrity ball valves and flow control solutions.

IMI plc offers a range of high-performance products, including integrity ball valves and advanced flow control solutions. These valves are engineered to provide precise control and long-lasting durability. You can depend on their integrity ball valves for applications where safety and accuracy are critical. Their flow control solutions optimize system performance, ensuring smooth and efficient operations.

Certifications include ISO 9001.

IMI plc adheres to strict quality standards, holding the ISO 9001 certification. This certification reflects the company’s commitment to delivering products that meet international benchmarks for quality and reliability. When you choose IMI plc, you gain confidence in the safety and performance of their solutions.

Innovations and Contributions

Advanced technologies and energy-efficient products.

IMI plc leads the way in adopting advanced technologies to enhance energy efficiency.

- The company develops low-emission alternative fuels, such as hydrogen, to support sustainable energy supply by 2050.

- Digitalization initiatives improve plant performance and streamline processes.

- IMI Insyt, a predictive maintenance solution, identifies potential system issues before they occur, ensuring safer and more efficient operations.

Tip: By integrating cutting-edge technologies, IMI plc helps you reduce downtime, lower emissions, and achieve operational excellence. Their focus on sustainability and innovation ensures you stay ahead in a competitive market.

DESCOTE(France)

Located in Lyon, an important industrial city in France. Since its establishment in 1956, DESCOTE has focused on the design and manufacture of high-quality bellows seals for extremely or highly hazardous media such as liquid chlorine, fluorine, phosgene, HCN, etc., requiring low emission and zero internal leakage in the chemical, petroleum and nuclear industries. Shut-off valve. DESCOTE bellows corrugated pipe seal globe valve is specially designed and manufactured for harsh working conditions and high requirements for safety and reliability, and enjoys a high reputation in the industry.

KSB (Germany)

KSB valves, based in Germany, rank among the world’s top three largest manufacturers of pumps and valves. Established in 1871, the company operates internationally with six factories in Germany and France. Renowned for its outstanding pump and valve solutions, KSB serves a diverse range of industries including water treatment, construction, energy, and industrial sectors.

Following a restructuring, KSB’s business is divided into three main segments: pumps, valves, and excellent services. Leveraging its pump market and customer base, KSB enhances the effectiveness of its valve products, providing optimal solutions to clients. Its business sectors encompass construction services, industrial and municipal water supply, energy, and mining. Under the PSA brand, KSB sells high-quality gate valves and ball valves in the energy and gas sectors, while under the MIL brand, it markets control valves produced by its Indian subsidiary, MIL Control Pvt. Ltd., with MIL valves enjoying particularly high brand recognition in Asia.

VELAN (Canada)

Velan, headquartered in Canada, was established in 1950 and is one of the world’s leading industrial valve manufacturers, especially in forged ball valves, forged gate valves, forged globe valves, forged check valves, and steam traps. Velan’s valves play a crucial role in key industries under high pressure, high temperature, or low-temperature conditions, including oil, natural gas, and nuclear energy sectors.

FAQ

What factors should you consider when choosing a valve manufacturer?

You should evaluate the manufacturer’s certifications, product range, and industry expertise. Check their reputation for quality and innovation. Ensure their valves meet your specific operational needs, such as pressure ratings or material compatibility. Reliable after-sales support is also essential.

Why are certifications important for valve manufacturers?

Certifications like ISO 9001 or API ensure the manufacturer adheres to international quality and safety standards. These certifications guarantee that the valves are reliable, durable, and compliant with industry regulations. Choosing certified manufacturers minimizes risks in critical applications.

How do smart valves improve operational efficiency?

Smart valves integrate real-time monitoring and predictive maintenance features. These technologies help you identify potential issues early, reducing downtime and maintenance costs. They also optimize system performance by providing precise control and actionable insights.

Which industries benefit most from advanced valve technologies?

Industries like oil and gas, water treatment, and power generation rely heavily on advanced valve technologies. These valves ensure safety, efficiency, and compliance with strict operational standards. They also support sustainability goals in sectors like manufacturing and energy.

What is the role of innovation in valve manufacturing?

Innovation drives the development of energy-efficient designs, advanced materials, and automation integration. These advancements enhance valve performance and durability. Manufacturers that prioritize innovation help you achieve operational excellence while meeting modern industrial challenges.

Tip: Always choose manufacturers that invest in research and development. Their innovative solutions ensure long-term reliability and efficiency.

If you’re looking for reliable, high-quality forged valves for your oil, natural gas, or nuclear power projects, look no further than Tianyu Valve. With over 20 years of experience, we offer tailor-made solutions to meet your specific operational needs. Our valves are designed to perform in extreme conditions, providing unmatched durability and efficiency.

Feel free to contact us today for more information or to request a quote. Our team is ready to assist you with any inquiries and ensure you get the best solution for your business.