Superior quality control is originated from advanced technology and equipment in line with international standards. Excellent modern digital fabrication equipment and unique process ensure our valve products. TIANYU are committed to quality and individual design to achieve the requirements of industrial modernization and pursue further progress.

The Tianyu quality control team carries out inspections in every step like casing, assembly, painting, packing and shipment, all pressure tests are in conformity with API598, API6D, API609,API527 and DIN3230 standards. The third party test is also welcome to insure the quality.

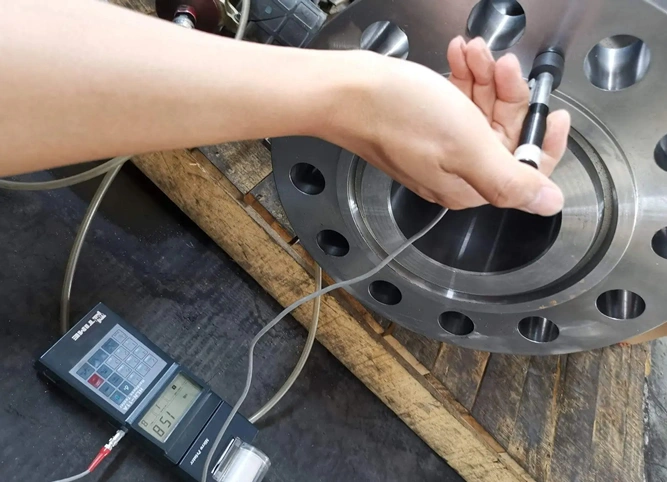

Ensuring Quality and Reliability, Our Industrial Valves Undergo Rigorous Quality Control Measures, Including Various Tests and Inspections.

Order and Design Stage: Customer requirements are determined, design is approved, order is placed, and production preparation begins.

Order and Design Stage: Customer requirements are determined, design is approved, order is placed, and production preparation begins.

Completion of Checklist Stage: Before production, check that all materials and resources are ready to ensure smooth production flow.

Production Process: Based on the design, manufacture the main valve components through precision machining, casting, and other techniques.

Assembly Stage: Assemble the manufactured components into a complete valve and perform an initial functional check.

Pressure Testing Stage: Conduct pressure testing on the assembled valve to ensure its sealing performance and reliability under high pressure.

TIANYU Valves implements a 6-Stage quality control system, including pressure testing and material analysis, to ensure industrial valves meet ISO/API/CE standards. Our quality inspection team, with over 10 years of industrial valve expertise, ensures every product meets global standards (ISO 9001, API6D, API609 CE).

With over 14 years of experience in the industry, our expert team of quality inspectors has the right skill set to ensure our valves pass global standards

Product and material testing is handled in-house via our testing laboratory, equipped with the latest testing equipment comparable to third-party professional facilities.

With over 10 years of experience in the industry, our expert team of quality inspectors has the right skill set to ensure our valves pass global standards

TIANYU Quality Control Procedure TIANYU Valve, quality is always at the forefront of our operations. We are fully committed to delivering industrial valves that excel in performance, quality, safety, and reliability. To uphold these standards, we have implemented a robust quality assurance system that aligns with the ISO 9001 quality assurance standard.

Our attention to detail in every processing step ensures the highest quality products. Our goal is to be the customers’ preferred choice for unique and innovative valve solutions that cater to their specific needs.

Tianyu Professional China Valve Manufacturers and Supplier Conforming ISO APl CE certification standards

Send us a message if you have any questions or request a quote. Our experts will give you a reply within 24 hours and help you select the right valve you want.

Founded in 2009, Wenzhou Tianyu Valve Technology Co., Ltd. is a professional valve enterprise integrating design, development, production, and sales services, located in the hometown of Chinese valves – Oubei Town, Wenzhou.

Copyright@2026 Tianyu Valve CO.,LTD. Sitemap All rights reserved.